The vacuum method of helium leak testing is a technique used to detect and locate leaks in a system or component by creating a vacuum and introducing helium gas as a tracer. Here’s how the vacuum method of helium leak testing typically works:

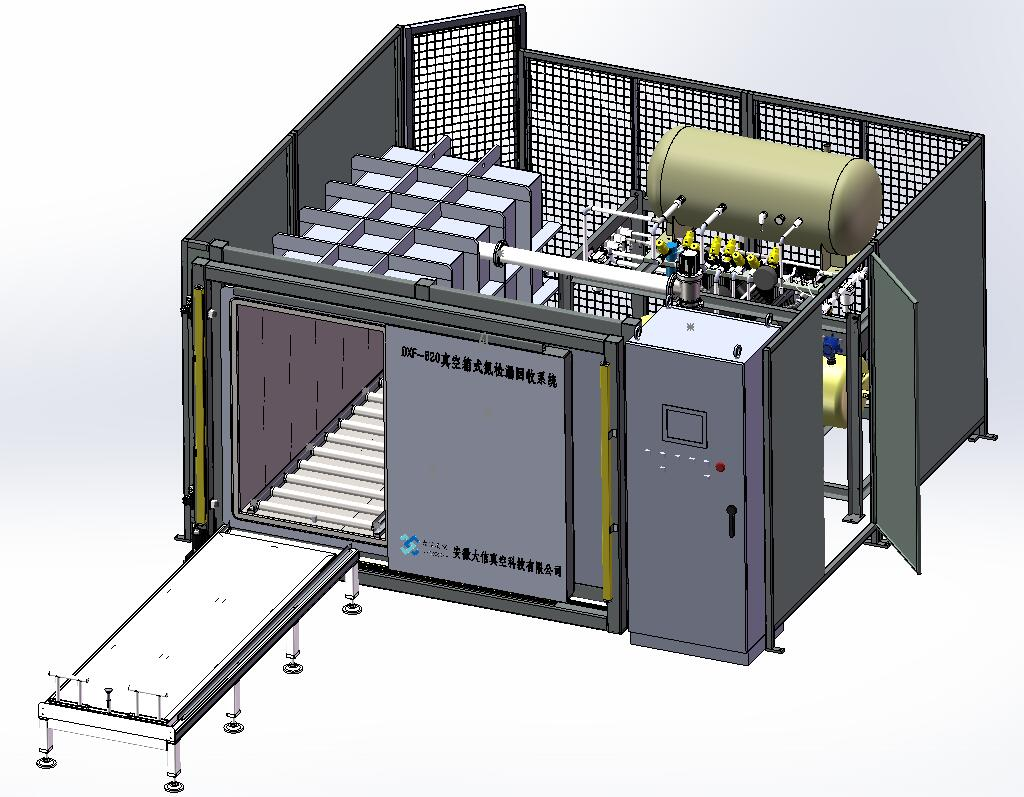

Prepare the Test Setup(vacuum chamber helium leak detecting system): Begin by setting up the test apparatus, which usually includes a vacuum chamber or a sealed test enclosure. Ensure that the system or component to be tested is properly connected to the test setup, with all necessary valves and connections in place.

Evacuate the System: Start by evacuating the test setup to create a vacuum. This is typically done using a vacuum pump, which removes air and other gases from the system. The goal is to achieve a low-pressure environment, usually in the range of 10^-3 to 10^-6 Torr, depending on the sensitivity required for the test.

Introduce Helium Gas: Once the desired vacuum level is reached, introduce helium gas into the test setup. Helium is used as a tracer gas because it is light, inert, and has extremely low concentration in the atmosphere. It can easily escape through even the smallest leaks and can be detected using specialized helium leak detectors.

Search for Helium Leak: With the helium gas introduced, use a helium leak detector to scan the system or component being tested. The leak detector is a sensitive instrument that can detect and measure the presence of helium gas. Move the leak detector probe along the surface of the test object, focusing on areas where leaks are most likely to occur, such as joints, seals, or connections.

Locate and Identify Leaks: As the leak detector probe approaches a leak, it will detect an increase in helium gas concentration. The leak detector will typically provide an audible or visual indication, such as an alarm or a meter reading, to signal the presence of a leak. By carefully moving the probe around the suspected area, you can pinpoint the exact location of the leak.

Evaluate and Repair Leaks: Once leaks are identified, evaluate their severity and determine the appropriate course of action. Depending on the nature and size of the leaks, repairs may involve tightening connections, replacing seals, or addressing other issues causing the leaks. After repairs are made, the system can be retested to ensure that the leaks have been successfully resolved.

The vacuum method of helium leak testing is commonly used in industries such as manufacturing, aerospace, automotive, and HVAC, where detecting and addressing leaks is crucial for safety, performance, and reliability. It is a sensitive and accurate method for locating even very small leaks in a system or component.