-

Challenges and Solutions Faced by Helium-Filled Recovery Systems

Introduction Helium-filled recovery systems play a crucial role in various industries, including aerospace, oil and gas, and scientific research. These systems are utilized to capture and recycle helium gas, which is an invaluable resource due to its unique properties. However, the operation and maintenance of helium-filled recovery systems present several challenges. This article will explore these challenges and propose potential solutions. Leak Detection and Control One of the primary challenges in helium-filled rec...

2023-10-12Learn More

> -

Maintenance of Vacuum Chamber Helium Leak Detection Systems

Introduction The maintenance of vacuum chamber helium leak detection systems is crucial to ensure optimal performance, accurate results, and prolonged equipment lifespan. These systems play a vital role in various industries that require leak-free environments, such as aerospace, semiconductor manufacturing, and scientific research. In this article, we will explore the essential aspects of maintaining vacuum chamber helium leak detection systems, providing valuable insights for industry professionals and technicians. Regular In...

2023-10-09Learn More

> -

The Significance of Helium Leak Rate Testing

Introduction In various industries such as aerospace, automotive, medical devices, and manufacturing, the detection and prevention of leaks is of utmost importance. Helium leak rate testing has emerged as a critical method for ensuring product reliability and safety. This article aims to explore the significance of helium leak rate testing and its applications across different sectors. Ensuring Product Integrity Helium leak rate testing plays a pivotal role in ensuring the integrity and quality of various products. By detectin...

2023-09-26Learn More

> -

Why is helium such a good element to be used as a leak detector?

Introduction When it comes to leak detection, helium has emerged as one of the most reliable and effective elements. Its unique properties make it an ideal choice for identifying leaks in various industries, from manufacturing and HVAC to aerospace and automotive. In this article, we will explore the reasons why helium is widely regarded as a superior leak detector. By understanding the advantages of helium, businesses can enhance their leak detection practices and ensure maximum efficiency in maintaining product quality and saf...

2023-09-19Learn More

> -

The Importance and Benefits of Recovering Helium

Introduction Helium, a highly versatile element with unique properties, has become an integral part of various industries. From healthcare to manufacturing, helium plays a vital role in processes that require cooling or a low-temperature environment. However, as the demand for helium grows while its availability depletes, it has become increasingly important to focus on recovering helium. In this article, we will explore the reasons why recovering helium is crucial and the benefits it offers. Understanding the Importance of R...

2023-09-12Learn More

> -

How to choose the right equipment for leak detection and Introduction to the Field of Vacuum and Ammonia Leak Detection

In the field of vacuum and ammonia leak detection, the use of helium-filled recovery systems and helium leak detectors has become increasingly important. These tools are essential for identifying leaks in refrigeration and air conditioning systems, as well as in industrial applications such as chemical processing and power generation. One of the key advantages of using a helium-filled recovery system is its ability to quickly and efficiently recover refrigerants and other gases from a system. This is particularly important in th...

2023-06-14Learn More

> -

Application of Helium Inspection Equipment in Electric Inflatable Switchgear Industry

Characteristics of SF6 application in electric gas filled cabinet industry 。SF6 is an artificial inert gas with a molecular weight of 146. It has good electrical insulation performance and excellent arc extinguishing performance. Its electric strength is 2.5 times that of nitrogen under the same pressure, its breakdown voltage is 2.5 times that of air, and its arc extinguishing capacity is 100 times that of air. It is a new generation of ultra-high voltage insulating medium material superior to that between air and oil....

2023-01-17Learn More

> -

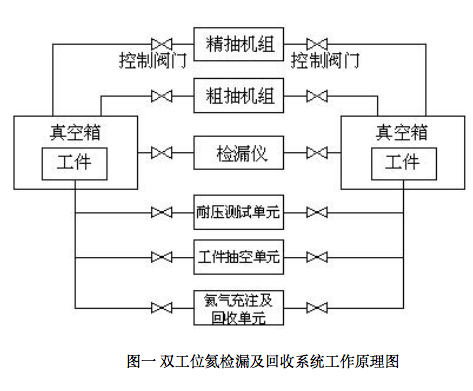

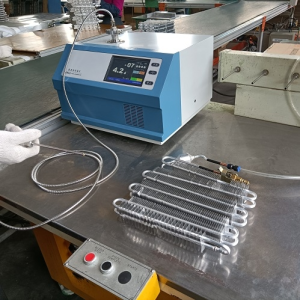

Application of helium leak detection and recovery system of vacuum chamber in automobile air conditioner

With the vigorous development of the domestic automobile industry, the state and the refrigeration industry have strict requirements on the annual leakage of the two condensers and evaporators of automobile air conditioners. The traditional water detection method has low accuracy and high error rate, which can no longer meet the requirements of modern automobile air conditioning detection standards. The helium mass spectrometer leak detection method has the advantages of high leak detection accuracy, low misjudgment rate, clean and...

2023-01-17Learn More

> -

Comparison of several leak detection methods and leak detectors

1.Hydrometric method This is the simplest and original leak detection method, which is used for bicycle tyres. It is to fill the tested work with air greater than atmospheric pressure. 1.0-3.0Mpa) Put it into the water to see if there are bubbles emerging from the workpiece. The location of bubbles is the location of leakage. The leakage rate can be estimated according to the rate of bubbles, the rate of bubbles and the size of bubbles. 2.Halogen method Previously, common refrigerators used halide as the refrigerant. When ...

2023-01-17Learn More

> -

Leak detection technology of aircraft wing integral fuel tank based on helium mass spectrometer leak detector

The sealing of wing integral fuel tank is the key in the manufacturing technology of wing box, and its sealing performance directly affects the service and safety of aircraft. The integral fuel tank of the wing has large volume and high sealing requirements. The traditional leak detection methods use air tight test and oil tight test. These methods have the disadvantages of low accuracy, high cost, difficult quantification, and low efficiency. In addition, the oil tight test requires a large amount of aviation kerosene to be inject...

2023-01-17Learn More

>