With the vigorous development of the domestic automobile industry, the state and the refrigeration industry have strict requirements on the annual leakage of the two condensers and evaporators of automobile air conditioners. The traditional water detection method has low accuracy and high error rate, which can no longer meet the requirements of modern automobile air conditioning detection standards. The helium mass spectrometer leak detection method has the advantages of high leak detection accuracy, low misjudgment rate, clean and environmental protection, and is increasingly widely concerned and recognized by the industry, and has the trend of gradually replacing water detection. Beijing Zhongke Scientific Instrument Co., Ltd. is a manufacturer engaged in the R&D and production of helium mass spectrometer in China. In order to meet the testing requirements of modern automobile air conditioners, it has independently developed and produced a helium leak detection and recovery system for vacuum chamber, which is widely used in many domestic manufacturers of the two devices. This paper briefly introduces the design principle of the system and its application in automobile air conditioning.

- Analysis of two leak detection methods: water detection and helium detection

At present, there are two leak detection methods: water detection and helium detection. The main leak detection methods for two air conditioners in China are: the advantages and disadvantages of the two leak detection methods will be analyzed below.

1.1 Detection and analysis of traditional bubble method

Bubble leak detection is a coarse leak detection method with low detection accuracy requirements. It is to fill the workpiece to be tested with dry compressed air or nitrogen under a certain pressure, and then put it into water to observe whether there are bubbles escaping from the workpiece to be tested. If there are bubbles, it indicates the leakage, and points out the location of the leakage. Generally, it is only necessary to determine whether the workpiece to be tested is leaking or not, rather than quantifying. But this does not mean that bubble leak detection cannot be quantified. In some cases, bubble leak detection can also be quantitative. The leak rate of the detected bubbles is related to the bubble diameter, bubble formation rate and the type of inflation.

Therefore, for leak detection of two air conditioners, the water detection method has low sensitivity. Influenced by human factors, the rate of missing and misjudging will increase significantly. In addition, after the water inspection of the workpiece, there is water on the outer surface, which needs drying treatment. This consumes more power and labor. However, the water detection method also has the advantages of simple and intuitive operation, and can find the location of the leakage point.

1.2 Analysis of Helium Mass Spectrometry Leak Detection Methods

Helium mass spectrometer leak detection is an ideal method for rapid location and quantitative detection of leaks in various containers that need to be sealed, using helium as the exploration gas.

Helium mass spectrometer leak detection method has the advantages of: helium is an inert gas, no pollution to the atmosphere, and safe to use; The helium atom has small mass, low viscosity and is easy to penetrate the possible leakage. The helium content in the atmosphere is small (5ppm), so it is not easily disturbed. Helium mass spectrometer leak detector has high sensitivity, fast speed and wide application range.

At present, the minimum detectable rate of helium mass spectrometer leak detector produced in China can reach 5.0 × 10-13 Pa·m3/s。 At present, the vacuum chamber method is widely used for leak detection of two air conditioners at home and abroad.

二、 Testing requirements for two units of automobile air conditioner

2.1 Actual working condition of two air conditioners

1、 Working medium of two air conditioners;Freon or hydrocarbons are used as refrigerants in automobile air conditioners, and R134a is currently popular as the refrigerant of automobile air conditioners.

2、Pressure range: The maximum working range of two air conditioners of different specifications is 2.0~3.5MPa, and the normal working pressure is 0.8~2.0MPa. Note: except for special circumstances.

3、Tightness requirements: for the two unit products, charge R134a refrigerant with a certain pressure, and the leakage is less than 2g/year.

4、Pressure resistance requirements: pressurize the product to the test pressure, maintain the pressure for a period of time, and reduce it to normal pressure. No leakage or abnormal deformation is found after inspection.

2.2 Basic requirements for helium leak detection of two air conditioners

1.Pressure withstand test requirements: generally, the two devices will be filled with high-purity nitrogen or dry compressed air at a certain pressure (generally not more than 3.5MPa) before helium leak detection, and the workpiece will be subject to pressure withstand test. If there is no obvious deformation and large leakage, the helium detection process will be carried out.

2.Helium detection accuracy requirements: Since different manufacturers have different detection requirements for products, they generally follow the industry standards or are slightly higher than the industry standards. Generally, the detection standard of “two detectors” will not exceed 1g/year.

3.Requirements for detection beat: According to the survey, the annual output of the general manufacturers of the two devices will be more than 100000. To realize the helium detection of all products, the faster the helium detection beat is, the better. The helium detection system produced by Zhongke Kemei has a leak detection beat of 40 seconds per condenser and 20 seconds per evaporator;

4.Requirements for helium recovery: the helium leak detection system uses helium as the tracer gas. Because helium is expensive, if it is directly discharged, it will inevitably lead to a significant increase in detection costs. Therefore, most manufacturers require helium to be recyclable, that is, recycled. Helium detection system, the helium recovery rate can reach more than 95%.

三、Working principle and composition of Vacuum chamber helium leak detection and recovery system

3.1 Basic principle of Vacuum chamber helium leak detection and recovery system

The back pressure method is used to detect the leakage rate of the tested workpiece, and the helium is recycled. First, put the inspected workpiece into the vacuum chamber, fill it with nitrogen at a certain pressure, and conduct a withstand voltage test. Determine whether there is a big leak by holding the pressure to determine the pressure drop; Then the tested workpiece is evacuated and filled with helium at a certain pressure. The vacuum chamber is connected with the leak detection port of the leak detector. If the tested workpiece leaks, the helium leaked into the vacuum chamber can be measured by the leak detector. Connected with the workpiece to be tested is an air charging recovery device, which realizes helium filling and recovery before and after leak detection.

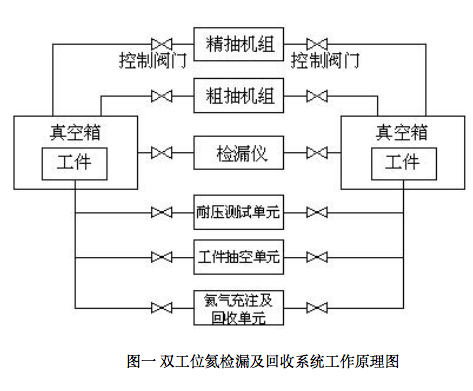

In order to meet the fast pace of industrial site detection, make full use of resources and save equipment manufacturing costs. The system adopts a dual station design. The schematic diagram of the system is shown in Figure 1. The two stations share a set of rough pumping unit, fine pumping unit, leak detector, withstand voltage test unit, workpiece evacuation unit, helium filling and recovery unit. The two stations can alternately execute different process flows. For example, when one station is leak detecting, the other station can execute evacuation, leak detection and other steps. According to this principle, we design a double station helium leak detection system.

3.2Composition of dual station helium leak detection system

(1) Rough pumping unit: generally, rotary vane pump or slide valve pump is used for rough pumping to obtain vacuum from one atmosphere to kilopascal and prepare for subsequent fine pumping.

(2)Fine pumping unit: Roots pump is generally used as fine pumping vacuum to obtain the vacuum required for leak detection, which is generally about 5Pa

Leak detector: it is the core component of the leak detection system. When the leak detector performs leak detection, it gives the leakage amount of the workpiece, judges whether the workpiece is qualified, and outputs control signals.

Withstand voltage test unit: It tests the withstand voltage performance of the workpiece by filling the workpiece with high-pressure gas. On the other hand, through the process of balancing and pressure maintaining, there are sensors to sense the pressure difference, and the control system determines whether there is a big leak through calculation and analysis.

Workpiece evacuation unit: in order to ensure the purity of helium in the process of helium circulation, extract the air in the workpiece before filling it with helium.

Helium filling and recovery unit: the helium filling process is: after the tested workpiece is evacuated, open V1, and close V1 after the workpiece is filled with helium to the specified pressure. After leak detection, V2 is opened, and helium in the workpiece automatically flows into the recovery tank. Then V2 is closed and V3 is opened, and the residual helium in the workpiece is pumped out by the mechanical pump and sent to the recovery tank. At the same time, the main compressor compresses the helium in the recovery tank to the gas storage tank. Because helium will be lost during the test, when the pressure in the gas tank is lower than the specified value, V6 needs to be opened to supplement helium to maintain sufficient pressure and concentration of helium in the gas tank.

四、Key technology of helium leak detection and recovery system design for vacuum tank

(1)First of all, it is necessary to ensure that the box is subject to inelastic deformation during the vacuum pumping process, causing the box to crack. Second, to ensure good air tightness, the vacuum chamber is generally formed by welding. According to the requirements of the vacuum system, the weld seam is free of air holes and contact marks, and the surface is smooth. After welding, the surface of the weld seam is polished and finally polished together with the box plate. The inner surface of the chamber treated in this way is smooth and clean, and there is less gas on the surface. Third, the vacuum chamber door can be opened and closed freely without scratching the box seal ring. In order to improve the service life of the box seal ring, the design should try to make the seal ring bear the force in the direction perpendicular to the flange face of the box, and try to avoid the oblique force.

(2)Vacuum pipeline design: In vacuum pipeline design, first consider that the pipeline flow guide should match the pumping speed of the vacuum pump to avoid the phenomenon that the horse pulls the trolley.

- Design of leak detection system: First, the system should have the function of detecting large, medium and micro leaks. Once the system has a large leak, it should immediately stop leak detection and give an alarm to prevent the helium detection process from continuing after a large leak occurs, causing the system to accumulate a large amount of helium and cannot be removed, which is also known as “helium poisoning”. Secondly, In case of major leakage, helium cleaning measures shall be taken to remove helium background to the greatest extent.

Helium filling and recovery design: First, ensure the safety. Because high-pressure gas is involved, the gas tank must be equipped with a safety valve and a timely pressure detection device to ensure the safety of the pressure vessel. Second, the pressure pipe must be well sealed to prevent the air from mixing into the system during inflation and recovery, which will cause the helium purity to drop. Third, a helium concentration detection device is required to ensure that fresh helium is added when the helium pressure and purity cannot meet the requirements. Fourth, oil filter is provided to prevent oil vapor in helium booster pump and vacuum pump from entering the gas tank and polluting the system.

五、Experience of helium leak detection system of vacuum chamber in leak detection of two reactors

5.1 Setting of alarm threshold of actual product leakage rate

When testing the two air conditioners, it is very important to set the product scrap point. If the indicator requirements are too high, a large number of products will be unqualified. If the indicators are too low, the product quality will not be guaranteed. The following steps are required to correctly determine the alarm point of the product:

(1)Convert refrigerant leakage rate into gas leakage rate

Gas is often used to replace refrigerant for leak detection of two air conditioners. Therefore, it is necessary to make an equivalent conversion between liquid leakage rate and gas leakage rate.

2.

First, the refrigerant liquid leakage rate is converted into the gas leakage rate:

3.Determine the shunt factor of the system

During the actual leak detection, due to the influence of the auxiliary pump and other factors, not all helium enters the helium leak detector, so there is a certain degree of diversion of helium. That is to say, the leakage rate indicated by the leak detector is not the actual leakage rate of the workpiece. To determine the shunt factor of the system, perform the following steps.

Adjust the instrument to the best working condition, place a standard leak with a known leak rate (Q1) in the vacuum box, open the system, observe the leak rate (Q2) indicated by the leak detector, and then the system shunt Q3=Q1/Q2.

(4)Determine the alarm point of the system

The alarm point of the workpiece can be determined according to the equivalent helium leakage rate obtained in (2) of this section and the system split flow factor obtained in (3):

Q= QHe/Q3。

5.2 Calibration of helium leak detection syste

After the helium leak detection system is used for a period of time, the leak detector may drift due to environmental and other factors. Therefore, the system needs to be calibrated regularly. System calibration is divided into internal calibration and external calibration.

(1)Internal calibration

Internal calibration refers to the calibration of the leak detector itself. To perform internal calibration, prepare a standard leak with known leakage rate to calibrate the leak detector. Due to the different calibration methods of each type of leak detector, this article will not elaborate due to space limitation. It is worth mentioning that some leak detectors have built-in standard leaks. The leakage rate of the built-in standard leak will decline after a period of use. Therefore, it is necessary to find a special unit of measurement to calibrate the built-in leak, which is usually calibrated once a year.

(2)External calibration

External calibration refers to the calibration of the whole leak detection system. After the system is used for a period of time, the shunt factor of the system may change. Therefore, it is necessary to calibrate the system with a standard leak regularly to determine whether the shunt ratio has changed. In case of change, it is necessary to adjust the alarm point of the system appropriately.

5.3Other precautions

- When using the helium leak detection system, some users hope that each box can detect multiple workpieces at one time to improve the detection efficiency. There are potential risks in doing so. First, there may be cumulative effect, that is, the cumulative leakage rate of multiple workpieces may exceed the alarm point, while the actual single workpiece is qualified within the allowable range. Second, once unqualified, a single re inspection is required, which consumes man hours. The basis for each box to detect multiple workpieces at one time is that the qualification rate of workpieces is more than 90% and the quality of workpieces is good.

(2)As the helium leak detection system is a kind of precision detection instrument, it is relatively demanding to the use environment. First, the workpiece shall be clean and dry. Second, the ambient temperature and humidity shall not be too high.

(3)In order to ensure the service life and stable operation of the system, the system needs regular maintenance. For example, replace the pump oil, clean the pipeline, replace the accessories, etc. If the conditions are not met, the manufacturer’s technicians must be invited for regular maintenance.